What is a ball screw assembly?

Ball screw nuts are used together with ball screws in an assembly referred to as a ball screw drive. The ball traverses along their aligned helical grooves. The ball screw drive converts rotary motion to linear motion with the help of recirculating metal balls. Ball nuts can force transmission to a moving load with high precision.

What are the components of a ball screw assembly?

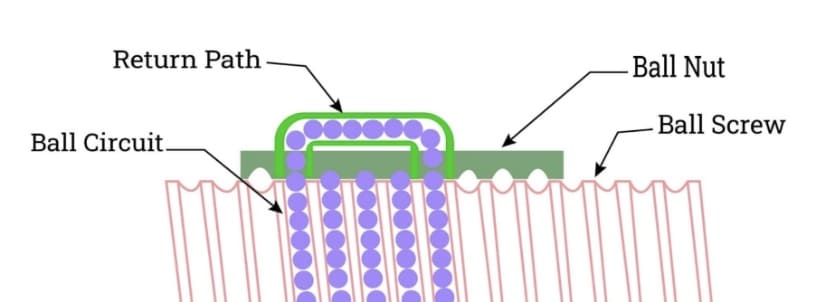

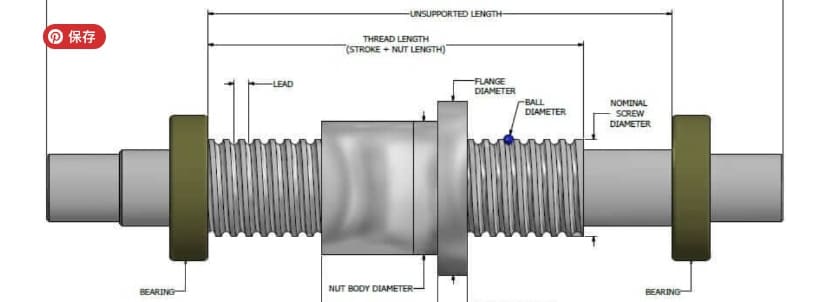

The important components of a ball screw assembly are the screw shaft, ball screw nut, and ball bearings (or balls). The ball screw nut is a precision-machined cylindrical component that houses the recirculating ball bearings and their return mechanism. The interior of the ball screw nut features ball grooves that match the threads of the ball screw shaft.

How does the ball screw assembly work?

The ball screw assembly works by converting the rotary movement of the shaft into linear movement of the nut. The ball bearings in a ball screw roll along the shaft on a track. As the ball recirculation system recycles the ball bearings, the nut is driven in a linear motion up the shaft.

Features of Ball Screw Assembly:

Ball screws offer a highly efficient means of converting rotary motion to linear motion.

Precision ball screws have several bearing balls that transfer the load between the nut and screw.

Greater accuracy

Longer and predictable life cycle

Improves speed, force, and duty cycle

Heavier loads

High efficiency (less friction)

Requires less motor power

Ball screw assembly applications:

CNC Machines

Ball screws drive the axes of lathes, mills, and routers.

Industrial Automation

Conveyor systems, packaging machines, and 3D printers use ball screws for consistent linear motion.

Robotics

In robotic arms, ball screws deliver smooth, repeatable motion for tasks like welding or pick-and-place. For example, FANUC robots assemble car parts with sub-millimeter accuracy.

Automotive Industry

Used in steering systems and assembly line actuators, ball screws provide responsive control and durability.

Aerospace

Aircraft rely on ball screws in flight control systems.

Medical Equipment

Precision matters in MRI tables, surgical robots, and prosthetic limbs.

RicoCNC can supply various Bosch Rexroth ball screw nuts, such as FEM-E-S type, FEM-E-B type, SEM-E-S type, SEM-E-C type, ZEM-E-S type, ZEV-E-S type, FDM-E-S type, and FDM-E-B type. If you have such needs, welcome your inquiry.